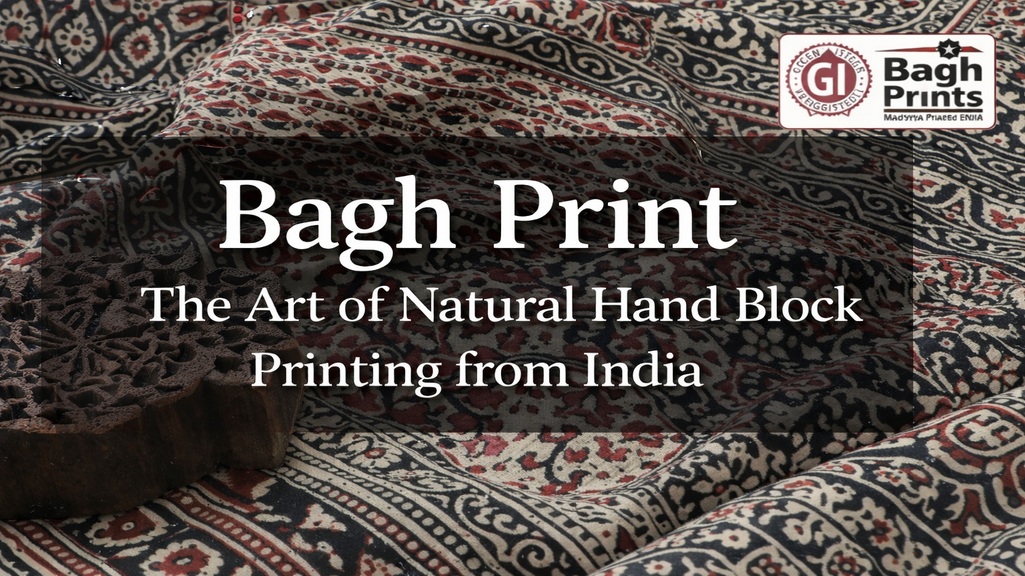

Bagh Print is a traditional hand block printing craft that originates from Bagh village in Madhya Pradesh, India. Known for its striking red, black, and off-white tones, Bagh Print is celebrated for its use of natural dyes and intricately hand-carved wooden blocks.

This eco-friendly textile art reflects India’s deep-rooted connection with nature, craftsmanship, and heritage. Bagh Prints of Madhya Pradesh received the GI tag in 2008, and the associated logo was registered in 2015.

History of Bagh Print

The craft of Bagh printing is believed to be over 300 years old, traditionally practised by the Khatri community. The name “Bagh Print” comes from the Bagh River, whose mineral-rich water played a vital role in achieving the signature colours of the print.

Over time, Bagh Print has evolved from traditional attire to contemporary products such as sarees, dupattas, suits, and home furnishings, while carefully preserving its original techniques.

The Bagh Print Process (Step-by-Step)

Bagh printing is a long and detailed process involving multiple stages. Each step is done by hand and requires great skill, patience, and experience.

1. Fabric Preparation (Khara Karna)

The cotton or silk fabric is thoroughly washed to remove starch and impurities. It is then treated with a mixture of rock salt, castor oil, and goat dung, which helps the fabric absorb natural dyes effectively.

2. Harara Treatment

The fabric is soaked in a solution made from harara fruit (myrobalan). This acts as a natural mordant and gives the fabric a light yellow tone, helping the colours bind strongly.

3. Hand Block Printing

Artisans use hand-carved wooden blocks dipped in natural dyes:

- Black is made from iron filings and jaggery

- Red comes from alum

Each block is carefully stamped by hand to create intricate, symmetrical patterns.

4. Drying & Washing in the River

After printing, the fabric is sun-dried and then washed in flowing water (traditionally, the Bagh River). This removes excess dye and enhances the clarity of the design.

5. Bhatti Process (Boiling)

The fabric is boiled in large copper vessels with alizarin and dhavda flowers. This step brings out the rich red and black colours and gives Bagh Print its signature depth.

6. Final Drying

The fabric is dried again under the sun, completing the process. The result is a beautifully printed textile with long-lasting, natural colours.

Women Artisan Empowerment

Women artisans play a crucial role in the Bagh printing process. From fabric preparation, dyeing, washing, drying, and finishing, their skills and dedication are deeply woven into every piece.

By participating in this craft, women artisans gain financial independence, preserve traditional knowledge, and support their families while passing skills across generations. Choosing Bagh Print not only keeps this heritage alive but also contributes to women’s empowerment and sustainable livelihoods in artisan communities.

Why Bagh Print Is Special

- 100% handcrafted

- Uses natural, eco-friendly dyes

- Sustainable and skin-friendly

- Supports traditional and women artisan communities

- Every piece is unique

Bagh Print in Modern Times

Today, Bagh Print is loved by designers and conscious consumers worldwide. It is used in:

- Sarees & dress materials

- Dupattas & stoles

- Cushion covers & curtains

- Contemporary ethnic wear

By choosing Bagh Print, you help preserve a centuries-old craft and support artisans—especially women—who keep this tradition alive.

Closing Note

Bagh Print is not just a textile—it is a story of patience, skill, and heritage printed by hand. Each piece carries the soul of the artisan, the strength of women behind the craft, and the timeless beauty of nature

One comment

porntude

A really good blog and me back again.